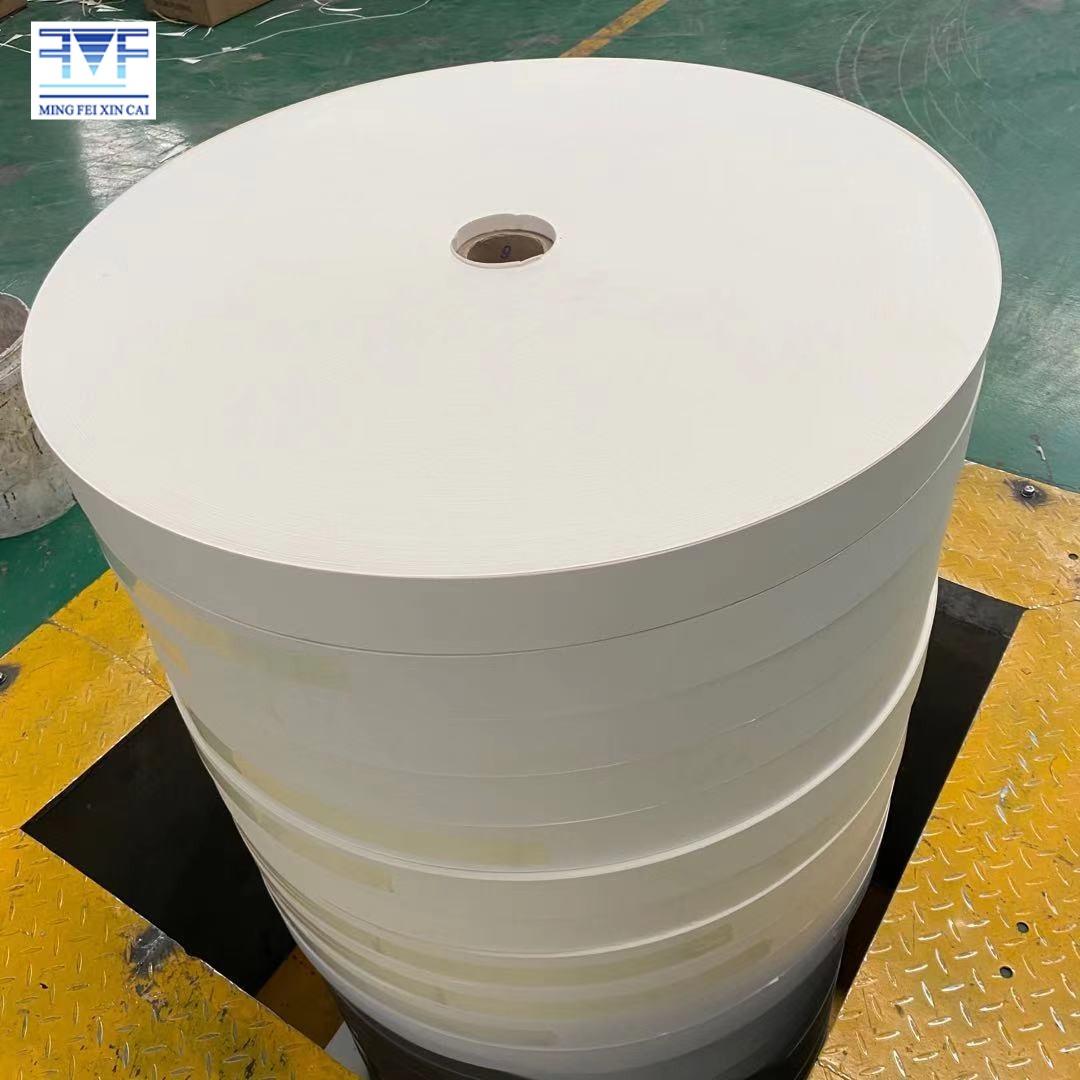

1. Paper Cup Fan:

Fan Structure: In the context of paper cup manufacturing, a "fan" refers to the fan-shaped piece of paper that is an integral part of a paper cup's construction. This fan provides structural support and shape to the cup.

Coated PE: The fan is coated with Polyethylene (PE), a thermoplastic polymer known for its moisture resistance and heat-sealing properties. The PE coating enhances the functionality of the paper cup.

2. Coated PE Blank Paper Cup Raw Material Fan:

Coated PE: The presence of a Polyethylene coating on the fan is a key feature. This coating provides moisture resistance, preventing the paper from becoming soggy when in contact with liquids.

Blank Nature: The term "blank" indicates that the fan is devoid of any pre-printed designs, logos, or branding elements. It is a clean slate, ready for customization during subsequent stages of cup production.

Raw Material: This fan serves as a raw material for the production of disposable paper cups. It undergoes further processing and customization before becoming the final cup product.

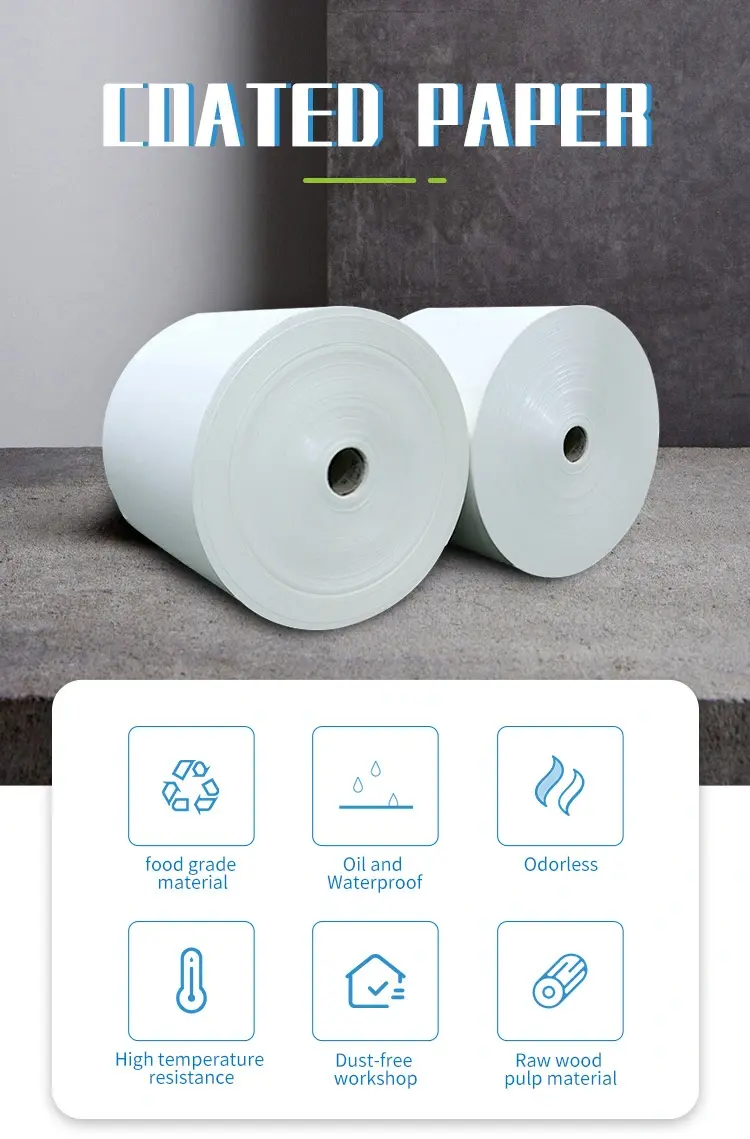

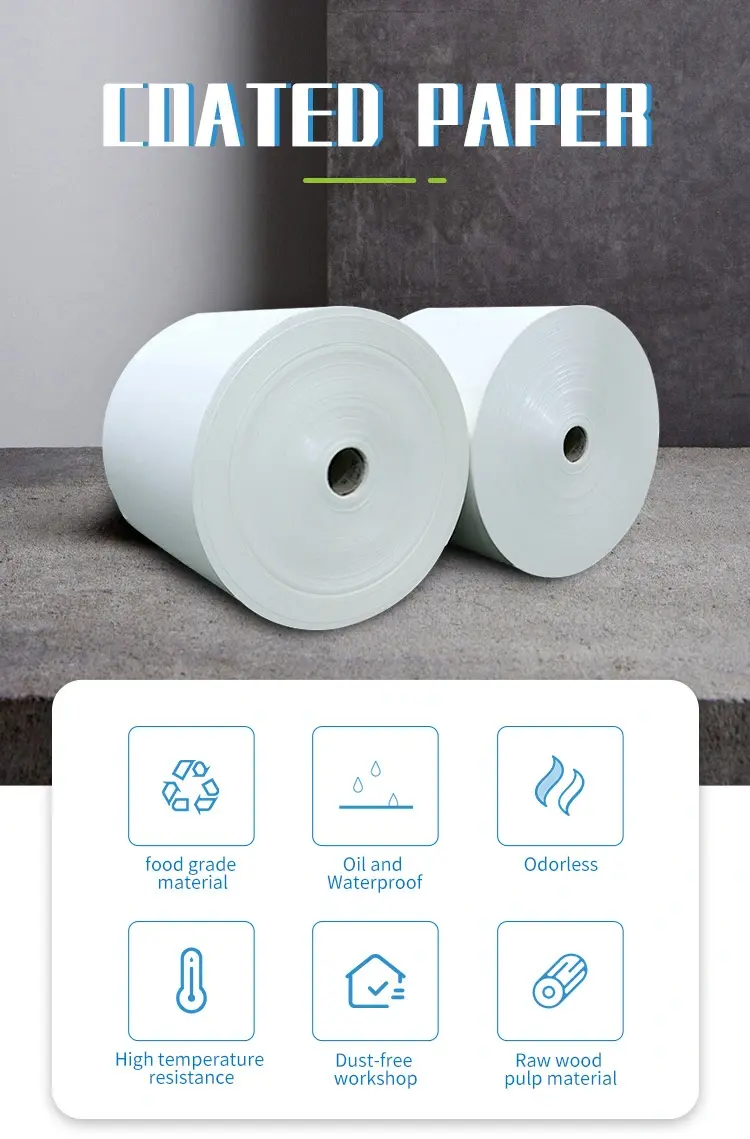

3. Characteristics:

Moisture Resistance: The Polyethylene coating adds a layer of moisture resistance to the fan, making it suitable for containing hot and cold beverages without compromising the cup's structural integrity.

Customization Potential: The blank nature of the fan allows for customization. Cup manufacturers can print logos, designs, or branding elements on the fan, contributing to the visual appeal of the final paper cup.

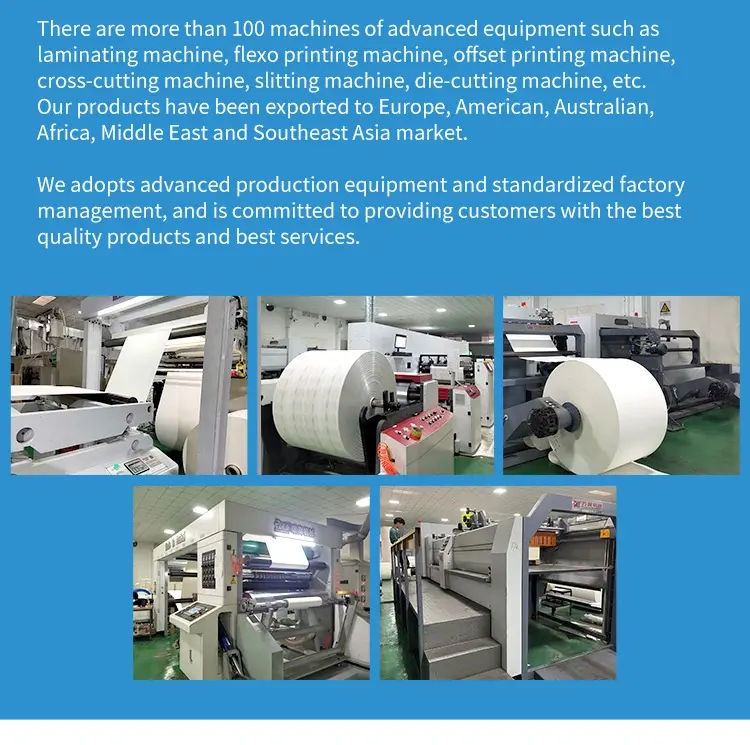

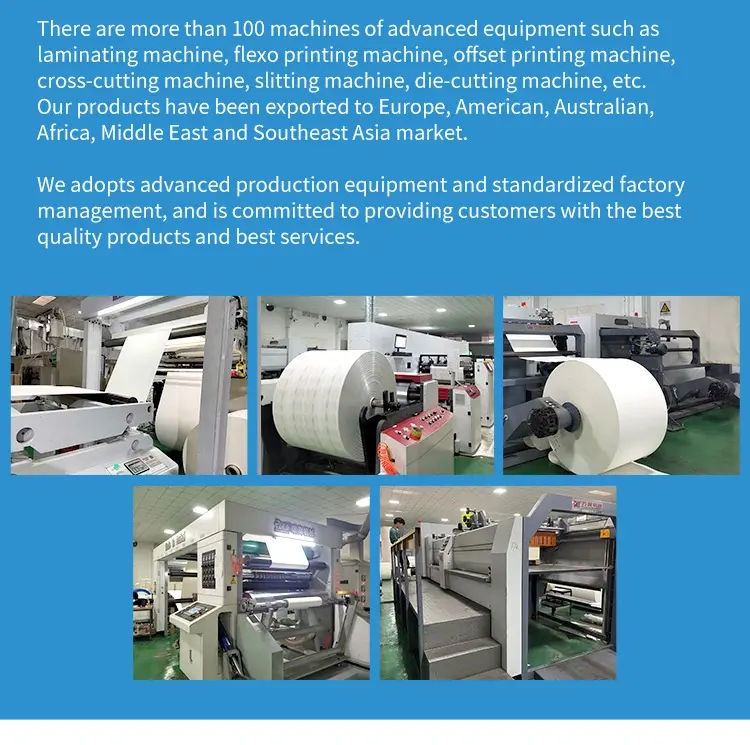

4. Manufacturing Process:

Coating Application: The base fan structure, usually made from high-quality paper, undergoes a coating process where a layer of Polyethylene is applied. This coating is often achieved through extrusion or lamination.

Cutting and Shaping: After the coating process, the fan is cut and shaped into the distinctive form required for paper cups. Precision in cutting is crucial for maintaining uniformity.

5. Applications:

Disposable Paper Cup Production: This raw material fan is specifically designed for the manufacturing of disposable paper cups. It plays a crucial role in providing strength, form, and functionality to the cups.

English

English Español

Español عربى

عربى.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

.jpg?imageView2/2/format/jp2)

-1.jpg?imageView2/2/format/jp2)

View More >>

View More >> View More >>

View More >> View More >>

View More >>.jpg?imageView2/2/format/jp2) View More >>

View More >>.png?imageView2/2/format/jp2) View More >>

View More >>.jpg?imageView2/2/format/jp2) View More >>

View More >> View More >>

View More >>.png?imageView2/2/format/jp2) View More >>

View More >> View More >>

View More >>-1.png?imageView2/2/format/jp2) View More >>

View More >> View More >>

View More >>