The raw material for a paper cup's PE coated layer is commonly referred to as PE Coated Paper Roll. This material plays a crucial role in the production of disposable paper cups, providing a combination of the strength and formability of paper with the protective properties of a Polyethylene (PE) coating.

Base Paper: The primary component is a base paper made from wood pulp. This paper is chosen for its strength, flexibility, and suitability for food-grade applications.

Polyethylene (PE) Coating: The base paper is coated with a layer of Polyethylene. PE is a thermoplastic polymer known for its moisture-resistant and heat-sealing properties, making it an excellent choice for enhancing the functionality of paper cups.

Key Features:

Moisture Resistance: The PE coating provides a barrier against moisture, preventing the paper from becoming soggy or losing its structural integrity when in contact with liquids, especially hot or cold beverages.

Heat Sealability: PE is heat-sealable, allowing for effective sealing during the manufacturing process. This feature is crucial for creating a leak-proof and durable bond in the seams of the paper cup.

Printability: The surface of the PE Coated Paper Roll is suitable for printing, enabling businesses to customize their paper cups with logos, branding elements, and designs. This printability enhances the aesthetic appeal of the final product.

Formability: The raw material is designed to be easily formable, allowing it to be shaped into the desired cup structure during the cup manufacturing process.

Manufacturing Process:

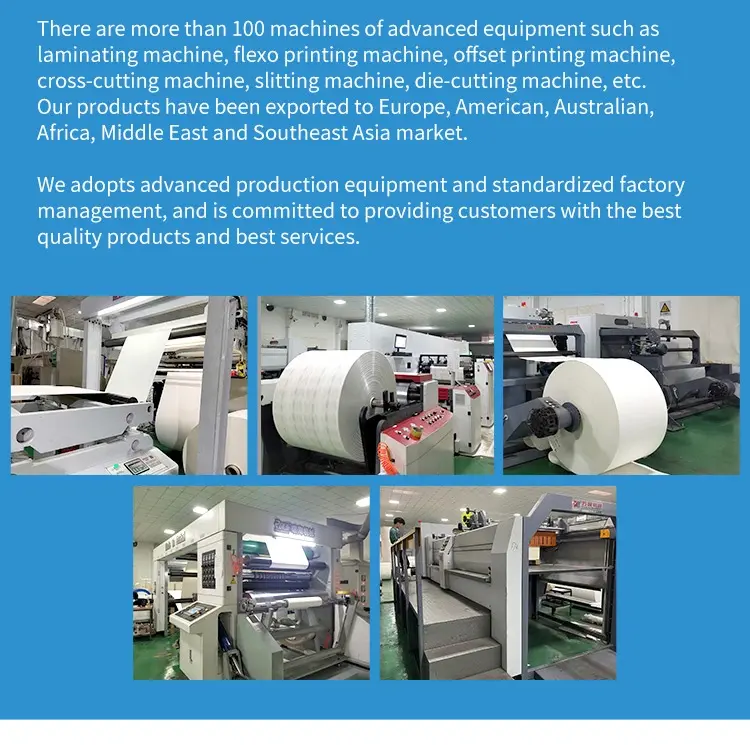

Coating Application: The base paper is passed through a coating process where a layer of Polyethylene is applied. This coating is often achieved through extrusion or lamination, ensuring uniform coverage.

Drying: After the coating process, the paper is dried to set the Polyethylene layer and ensure proper adhesion.

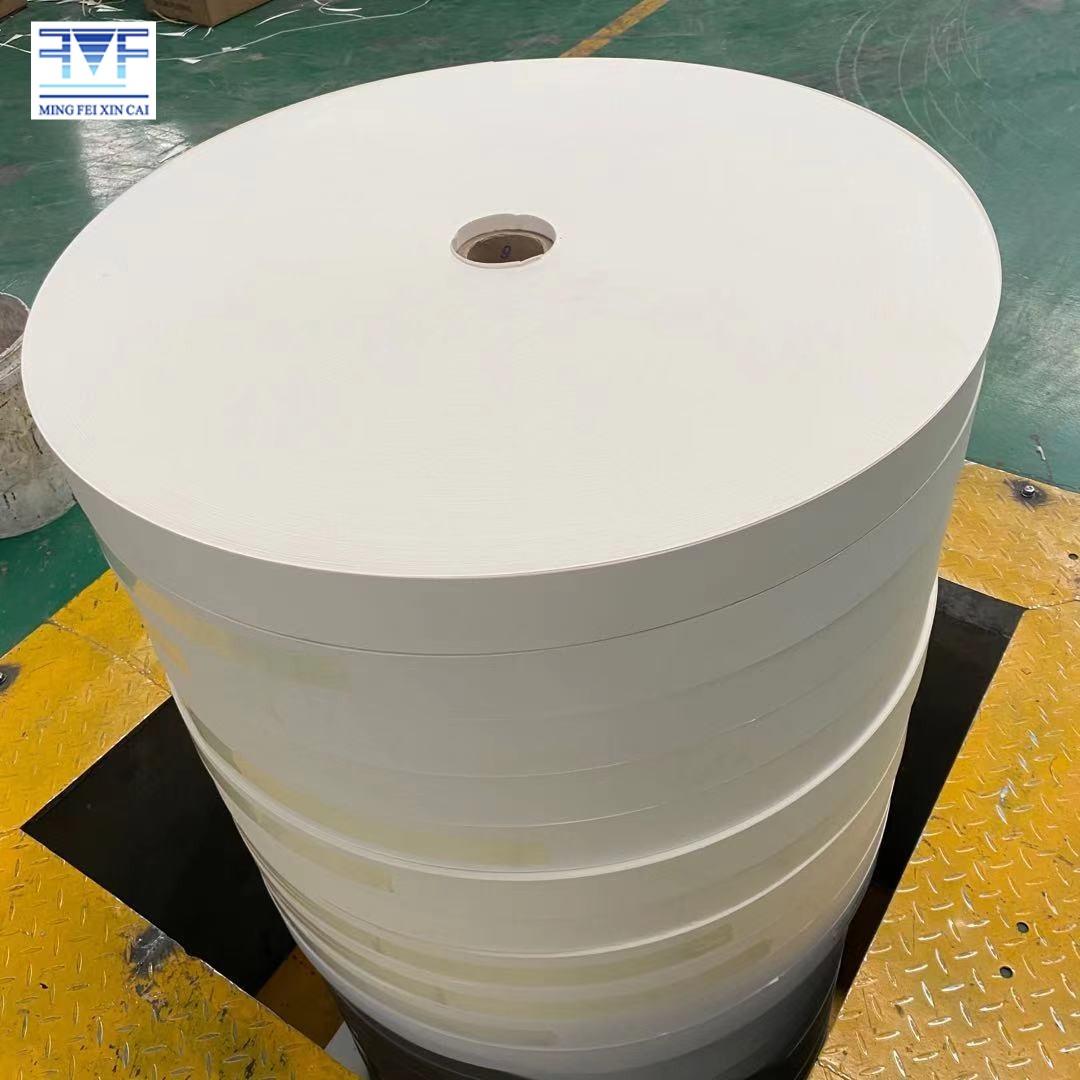

Roll Formation: The coated paper is then rolled into large rolls, creating the PE Coated Paper Roll. These rolls are the raw material used in the production of paper cups.

Applications:

Paper Cup Production: The primary application of PE Coated Paper Rolls is in the manufacturing of disposable paper cups. The moisture resistance and heat-sealing properties make it ideal for containing hot and cold beverages.

Other Food Packaging: Besides cups, PE coated paper finds applications in various other food packaging products like plates, bowls, and food containers.

English

English Español

Español عربى

عربى

View More >>

View More >> View More >>

View More >> View More >>

View More >>.jpg?imageView2/2/format/jp2) View More >>

View More >>.png?imageView2/2/format/jp2) View More >>

View More >>.jpg?imageView2/2/format/jp2) View More >>

View More >> View More >>

View More >>.png?imageView2/2/format/jp2) View More >>

View More >>.jpg?imageView2/2/format/jp2) View More >>

View More >>-1.png?imageView2/2/format/jp2) View More >>

View More >> View More >>

View More >>