PE coated paper cup fans have become integral components in the production of disposable cups, providing a blend of strength, insulation, and moisture resistance. These cup fans are designed to meet the diverse needs of the food and beverage industry, particularly in serving hot and cold beverages.

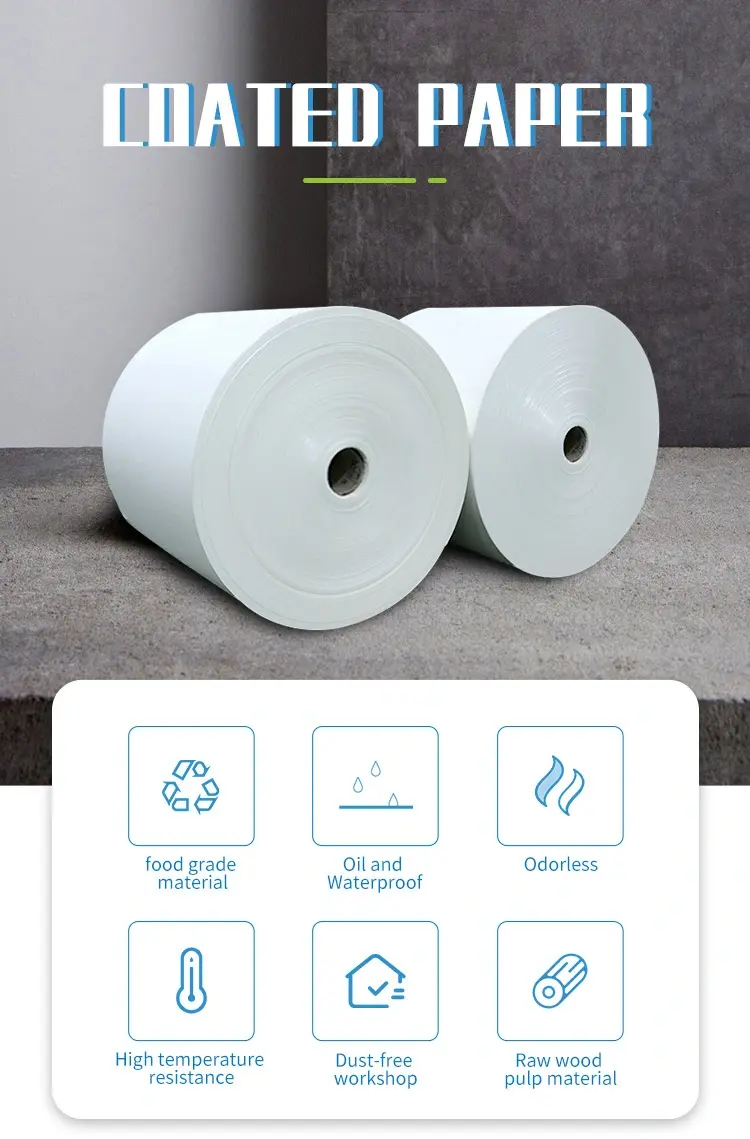

PE coated paper cup fans are typically composed of two primary layers — a base layer of paper and an outer layer of polyethylene (PE). The paper component is derived from wood pulp, often sourced from sustainable and responsibly managed forests. This layer serves as the foundation, providing the necessary structural support for the cup.

The polyethylene layer, applied through extrusion coating, acts as a crucial barrier against moisture. This coating ensures that the cup remains resilient even when in contact with liquids, making it suitable for a variety of beverage applications.

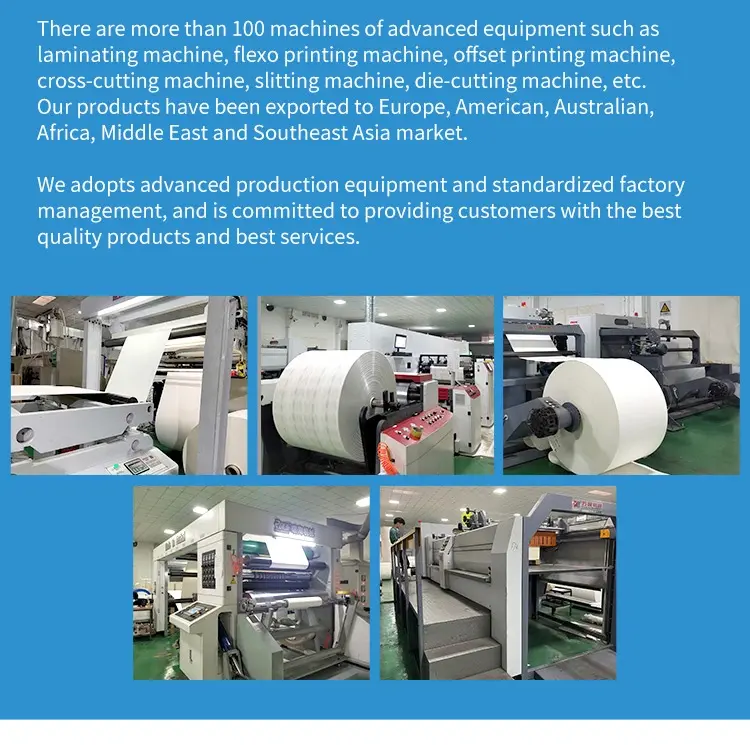

The production of PE coated paper cup fans involves a precise and controlled coating process. The paper is coated with a thin layer of polyethylene using extrusion coating machinery. This method allows for an even distribution of the PE layer on one or both sides of the paper.

Following the coating process, the material undergoes a drying phase to eliminate any residual moisture. Once dried, the PE coated paper is cut into fan-shaped sheets. These sheets serve as the starting point for forming the final cups through subsequent manufacturing steps.

PE coated paper cup fans are available in various sizes to accommodate different beverage volumes. Common sizes include 6oz, 7oz, and larger capacities. This versatility allows for the production of cups suitable for single servings as well as larger portions, catering to the diverse needs of consumers and businesses.

One of the notable advantages of PE coated paper cup fans is their ability to resist heat. The polyethylene layer acts as a protective barrier, preventing the transfer of excessive heat to the outer surface of the cup. This feature is particularly important for cups used to serve hot beverages like coffee and tea.

The insulation provided by the PE coating helps in maintaining the temperature of the beverage, keeping it hot or cold for a longer duration. This enhances the overall drinking experience for consumers.

While PE coated paper cups offer convenience for single-use applications, there is an increasing focus on addressing environmental concerns. Efforts are being made to source paper from sustainable forests, and advancements in recycling technologies aim to tackle the challenges associated with the combination of paper and plastic layers.

Biodegradable and compostable alternatives are also being explored to minimize the environmental impact of disposable cups. Manufacturers are actively seeking eco-friendly solutions without compromising the performance and functionality of PE coated paper cups.

PE coated paper cup fans find widespread applications in the food and beverage industry. They are commonly used in cafes, restaurants, fast-food establishments, and various events.

These cups are suitable for serving a diverse range of beverages, including coffee, tea, soft drinks, and more. Their disposable nature adds to their convenience, making them popular choices for consumers on the go.

English

English Español

Español عربى

عربى

View More >>

View More >> View More >>

View More >>.jpg?imageView2/2/format/jp2) View More >>

View More >>.png?imageView2/2/format/jp2) View More >>

View More >>.jpg?imageView2/2/format/jp2) View More >>

View More >> View More >>

View More >>.png?imageView2/2/format/jp2) View More >>

View More >> View More >>

View More >>.jpg?imageView2/2/format/jp2) View More >>

View More >>-1.png?imageView2/2/format/jp2) View More >>

View More >> View More >>

View More >>